PVC Manufacture

Basically, PVC products are formed from raw PVC powder by a process of heat and pressure. The two major processes used in manufacture are extrusion for pipe and injection moulding for fittings.

Modern PVC processing involves highly developed scientific methods requiring precise control over process variables. The polymer material is a free flowing powder, which requires the addition of stabilisers and processing aids. Formulation and blending are critical stages of the process and tight specifications are maintained for incoming raw materials, batching and mixing. Feed to the extrusion or moulding machines may be direct, in the form of “dry blend”, or pre-processed into a granular “compound”.

Extrusion

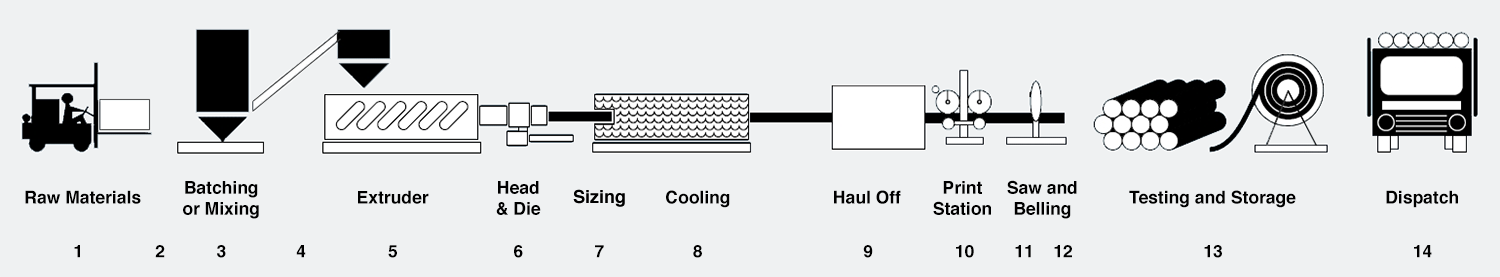

Polymer and additives (1) are accurately weighed (2) and processed through the high speed mixing (3) to blend the raw materials into a uniformly distributed dry blend mixture. A mixing temperature of around 120°C is achieved by frictional heat. At various stages of the mixing process, the additives melt and progressively coat the PVC polymer granules. After reaching the required temperature, the blend is automatically discharged into a cooling chamber which rapidly reduces the temperature to around 50°C, thereby allowing the blend to be conveyed to intermediate storage (4) where even temperature and density consistency are achieved.

The heart of the process, the extruder (5), has a temperature-controlled, zoned barrel in which rotate precision “screws”. Modern extruder screws are complex devices, carefully designed with varying flights to control the compression and shear, developed in the material, during all stages of the process. The twin counter-rotating screw configuration used by all major manufacturers offers improved processing.

The PVC dryblend is metered into the barrel and screws, which then convert the dry blend into the required “melt” state, by heat, pressure and shear. During its passage along the screws, the PVC passes through a number of zones that compress, homogenise and vent the melt stream. The final zone increases the pressure to extrude the melt through the head and die set (6) which is shaped according to the size of the pipe required and flow characteristics of the melt stream. Once the pipe leaves the extrusion die, it is sized by passing through a precision sizing sleeve with external vacuum. This is sufficient to harden the exterior layer of PVC and hold the pipe diameter during final cooling in a controlled water cooling chambers (8).

The pipe is pulled through the sizing and cooling operations by the puller or haul-off (9) at a constant speed. Speed control is very important when this equipment is used because the speed at which the pipe is pulled will affect the wall thickness of the finished product. In the case of rubber ring jointed pipe the haul-off is slowed down at appropriate intervals to thicken the pipe in the area of the socket.

An in-line printer (10) marks the pipes at regular intervals, with identification according to size, class, type, date, Standard number, and extruder number. An automatic cut-off saw (11) cuts the pipe to the required length.

A belling machine forms a socket on the end of each length of pipe (12). There are two general forms of socket. For rubber-ring jointed pipe, a collapsible mandrel is used, whereas a plain mandrel is used for solvent jointed sockets. Rubber ring pipe requires a chamfer on the spigot, which is executed either at the saw station or belling unit.

The finished product is stored in holding areas for inspection and final laboratory testing and quality acceptance (13). All production is tested and inspected in accordance with the appropriate Australian Standard and/or to specifications of the purchaser.

After inspection and acceptance, the pipe is stored to await final dispatch (14).

For oriented PVC (PVC-O) pipes, the extrusion process is followed by an additional expansion process which takes place under well defined and carefully controlled conditions of temperature and pressure. It is during the expansion that the molecular orientation, which imparts the high strength typical of PVC-O, occurs.

Injection Moulding

PVC fittings are manufactured by high-pressure injection moulding. In contrast to continuous extrusion, moulding is a repetitive cyclic process, where a “shot” of material is delivered to a mould in each cycle.

PVC material, either in dry blend powder form or granular compound form, is gravity fed from a hopper situated above the injection unit, into the barrel housing a reciprocating screw.

The barrel is charged with the required amount of plastic by the screw rotating and conveying the material to the front of the barrel. The position of the screw is set to a predetermined “shot size”. During this action, pressure and heat “plasticise” the material, which now in its melted state, awaits injection into the mould.

All this takes place during the cooling cycle of the previous shot. After a preset time the mould will open and the finished moulded fitting will be ejected from the mould.

The mould then closes and the melted plastic in the front of the barrel is injected under high pressure by the screw now acting as a plunger. The plastic enters the mould to form the next fitting.

After injection, recharge commences while the moulded fitting goes through its cooling cycle.