PRO & FLO Below Ground Installation

Vinidex StormPRO® and StormFLO® pipes are twin-wall, corrugated polypropylene pipes for non-pressure applications, and can be installed in non-trafficable and trafficable areas, including under road pavements.

This guide is intended to provide general information for the safe installation of Vinidex StormPRO® and StormFLO® pipes. For more detailed information refer to AS/NZS 2566.2 “Buried flexible pipelines: Part 2, Installation”.

For correctly designed and installed systems, the service life can be expected to be at least 100 years before major rehabilitation is required.

Flexible pipes

Vinidex StormPRO® and StormFLO® are flexible pipes. This means that as vertical loads are applied, the pipe will deflect and take advantage of horizontal soil pressure to provide additional support. After initial compaction and settlement, applied vertical loads have very little effect on deflection.

Rigid pipes, such as steel reinforced concrete pipes do not deflect, and are designed to carry all applied vertical loads caused by soil and traffic. The surrounding soil provides little or no horizontal support to a rigid pipe. Notwithstanding this, proper placement and compaction of bedding material around rigid pipes is critical in minimising the load on the pipe.

Flexible pipes have some ability to deform without structural damage and provide designers and installers with a wide range of advantages.

The structural action and design methodology of flexible pipes is well understood. Their use in all buried applications and particularly under road pavements is well established throughout the world and in Australia.

As flexible pipes transfer load through deflection, loading outside design parameters leads mostly to deformation without structural damage. Overloading results in cracking of rigid pipes. Flexible pipes provide a substantial insurance for operational conditions outside design parameters.

Handling and Storage

StormPRO® and StormFLO® pipes are robust and are suitable for use in all site conditions. The pipes are relatively light weight and can generally be manhandled. However, care should be taken when pipes are loaded, unloaded, stacked or distributed on sites.

When pipes are lifted mechanically, web or rope slings should be used. Pipes should not be allowed to overhang by more than 1 metre. Transport should not have sharp projections which could cause damage to pipes. Pipes should not be dragged along the ground as this can damage the pipe, causing difficulty with jointing and testing.

StormPRO® and StormFLO® pipes should be stacked on flat firm ground, which has been cleared of debris. Pipes should be laid flat on transverse bearers at least 75mm wide at maximum 1.5m centres.

Pipe sockets should be supported so that the ends are free from loading, with sockets in each layer opposite to the previous layer. Different sizes are best stacked separately. If this is not practical, then stack with the largest pipes at the base. Framed crates must be stored timber on timber and may go up three crates but should not exceed 3m in height. If pipes are to be nested for long periods, stacks should not exceed 2m in height.

Rubber rings should be stored away from direct sunlight or weathering. Rubber rings should never be placed on the ends of pipes which are being stored.

StormPRO® and StormFLO®

Installation: Handling and Storage Video

For more information on handling and storage refer to the video below:

Trench dimensions

There are a number of video resources available in addition to the text below that cover trench preparation, side support, fill and cover heights. To view these videos, please refer to our Stormwater and Underground Drainage Systems Support Page.

Preparation

The trench should not be excavated too far in advance of pipe laying and should be backfilled as soon as possible.

Minimum Trench Width

The trench width should be as narrow as is practicable but wide enough to allow adequate compaction of the haunch zone.

Pipes in parallel

Where pipes are laid in parallel, the minimum spacings between pipelines are given in the Table below.

Minimum spacings between parallel pipes

| Nominal Diameter (mm) | Minimum Spacing (mm) |

| 150 | 150 |

| 225 | 150 |

| 300 | 200 |

| 375 | 200 |

| 450 | 300 |

| 525 | 300 |

| 600 | 300 |

| 750 | 300 |

| 900 | 350 |

The trench should be excavated deep enough to allow for the specified grade, the required depth of underlay and the minimum cover. General dimensions and recommended minimum cover are given in the Table below.

Minimum Cover Over Pipe

| Loading Condition | Minimum Cover (mm) |

| Not subject to vehicular loading:

a) Without pavement – |

|

| i. for single dwellings; or |

100 |

| ii. for other than single dwellings | 300 |

| b) With pavement of brick or unreinforced concrete |

100* |

| Subject to vehicular loading:

a) Other than roads: |

|

| i. Without pavement | 450 |

| ii. With pavement of – | |

| A. reinforced concrete for heavy vehicular loading |

100* |

| B. brick or unreinforced concrete for light vehicular loading |

75* |

| b) Roads – | |

| i. sealed; or | 600 |

| ii. unsealed | 750 |

| Subject to construction equipment loading or in embankment conditions | 750 |

| Land zone for agricultural use | 600 |

| *Below the underside of the pavement

NOTE: Values shown in red are to be used only where AS/NZS 3500.3 is applicable.

|

Selection of Embedment Material

Embedment material for pipes should preferably be granular, free-flowing material. This type of embedment material requires less compactive effort to provide support for the pipe and minimise soil settlement.

The most common embedment material is 5-7mm crushed rock. A typical grading is shown in the Table below.

| Sieve Size (mm) | 9.5 | 6.7 | 4.75 | 2.36 | 1.18 |

| % Passing by Mass | 100 | 85-100 | 30-85 | 0-30 | 0-5 |

Where sand is more readily available, a typical sand grading is shown in the Table below.

| Sieve Size (mm) | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| % Passing by Mass | 100 | 90-100 | 85-100 | 70-100 | 50-100 | 0-40 | 0-5 |

Placing and compacting embedment material

The bedding material should be placed and graded to invert level, and compacted as required (refer to Structural Design). In conditions where the trench bottom is wet, soft or irregular, it may be necessary to first stabilise, fill and level, and compact the base. Place and compact material in the pipe bedding zone to minimum depth of 75mm beneath the pipe.

In order to ensure uniform support along the pipe barrel, a small indentation should be excavated in the pipe bedding zone to accommodate the pipe sockets. The pipe side support material should be placed evenly on both sides of the pipeline and compacted such that relative compaction is consistent with design. Side support material should be worked under the sides of the pipe to minimise voids and provide maximum pipe haunching, taking care to minimise distortion of the pipe and maintain alignment and grade.

The pipe overlay material should be levelled and compacted in layers, to a minimum height of 150mm above the crown of the pipe, or as specified.

Backfilling

Backfill should be placed on the pipe overlay and compacted as specified but generally not in layers in excess of 300mm.

Complete the backfilling operation to finished surface level.

Construction Loads

During construction, consideration of loading during placement and compaction of fill around the pipe and any other construction loading is critical. Care must be taken to ensure that any construction loading from trench compaction and road construction equipment does not overload the pipe.

The following minimum depths of compacted fill over the pipe apply for the placement and compaction of fill around StormPRO® and StormFLO®

| Construction Load | Minimum cover StormPRO® ^ | Minimum cover StormFLO® ^ |

| CAT140H Grader (17t) | 400mm | 400mm |

| CAT325B Excavator (25.9t) | 400mm | 400mm |

| CAT815F Compactor (20.9t) | 400mm | 400mm |

| Vibratory Trench Roller (2t) | 400mm | 400mm |

| Vibratory Plate (135kg) | 400mm | 400mm |

| Vibratory Rammer (75kg) | 400mm | 400mm |

| Smooth Drum Vibratory Roller (10t) | 700mm | 700mm |

| CATD25D Articulated Truck (42.3t) | 650mm | 650mm |

| 25t Excavator and Compaction Wheel | 1000mm | 1000mm |

^ Values derived from AS/NZS 2566.1 (short-term ring bending stiffness)

Flotation

The possibility of pipe flotation exists when pipe is installed in areas which will be inundated, such as creek crossings, flood plains and high groundwater areas. To prevent flotation, a minimum cover equivalent to 75% of the nominal diameter is required.

Concrete Encasement

Where concrete encasement is required, pipes should be laid to the correct alignment and grade, supported on hessian bags filled with stabilised sand or on concrete blocks or cradles.

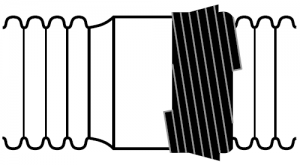

The concrete surround should be placed so as to provide uniform and continuous support around the entire circumference of the pipe. StormPRO® joints for concrete encasement should be made with an additional rubber ring. For pipe sizes up to and including DN300, a gap should be left and the extra ring placed in the valley between the third and fourth corrugations from the spigot end. For sizes DN375 and greater, the second ring should be placed adjacent to the first ring in the valley between the second and third corrugations. DN750 and DN900 have rings in the first two valleys as usual. The table below outlines placement of additional rings.

| DN150 to DN300 | DN375 to DN600 | DN750 to DN900 |

The completed joint should also be sealed with tape to prevent concrete entering the socket during encasement.