Design stress ratings for plastics pipes (VX-TN-3B)

Introduction

The properties of plastics are time and temperature dependent. Therefore, plastics pipes, which require long service lives, are designed on the basis of their long term rather than their short term mechanical properties. The significance of this design point is frequently misunderstood. This technical note discusses the methodology for determining the design stress and the interpretation of the design point.

Long term testing

The aim of long term testing is to determine a stress which may be continuously applied to a pipe over its service life. The testing involves subjecting pipe samples to various levels of internal pressure and measuring the time to rupture. Pipe test samples with high internal pressures will fail in shorter times whereas the pipes subjected to lower pressures will survive for long periods.

It is obviously quite unrealistic to carry out tests for time periods any where near the intended service life of pipes which may be over a hundred years. Therefore, high pressures and sometimes elevated temperatures are used to accelerate the testing and the results are analysed mathematically.

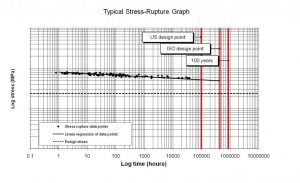

A large number of samples must be tested to ensure that the results are statistically significant and truly representative of the performance of the material. The results for each sample are plotted on a graph of the wall stress due to internal pressure versus the time to rupture. Both axes on this stress rupture graph have a logarithmic scale.

It is important to recognise this point: that the characteristic stress rupture curve is composed of a large number of discrete points from separate samples. It therefore does not imply that plastics materials lose strength with time as is sometimes claimed.

Regression analysis

The data are analysed by ‘regression analysis’, to find the line of best fit. Once the characteristic curve of rupture stress versus time under continuous load has been established, the graph is extrapolated to a standard design point (time).

As well as the mean line of best fit, the 97.5% lower prediction limit is usually determined. This latter term is a statistical term which predicts the stress, for a given time, at which 97.5% of samples will not have ruptured. The amount this deviates from the mean line of best fit through the data is a measure of the amount of scatter in the data.

For materials like PVC, the data follows a straight line on the log-log axes and a linear regression analysis is used. Where this is the case, extrapolation is simple and has a high degree of confidence.

Other materials such as polyethylene are more complex, and may have a change in slope or ‘knee’ in the curve at long times. Fortunately, this behaviour follows a known relationship and with additional testing at other temperatures and some further analysis, the position of the knee can be identified.

The Design Point

Product standards for plastics pipes materials specify a minimum value for the extrapolated hoop stress or 97.5% lower prediction limit for each material grade. This value is known as the Minimum Required Strength or MRS.

The design hoop stress is determined from the MRS by the application of a suitable design factor. This is to provide a margin to cope with any unpredicted stress conditions (including temperatures) that may arise in service. So PVC pipes, for which the extrapolated hoop stress at the 50 year design point must exceed 23.6 MPa, have a design stress of 11MPa, with a factor of safety of just over 2.

The design point is chosen at some long period of time where the slope of the curve is so low that further change may be considered insignificant in the context of the design factors applied

In Europe, and Australia, the ISO design point of 50 years is adopted. This is commonly misused (by those who wish to misuse it) to suggest that the life of PVC pipes is only 50 years. This is of course nonsense: 50 years is an arbitrary design point, and could be any period – 100 or 1000 years for that matter. The Americans (ASTM) use 100,000 hours (about 11 years) instead, but nobody suggests that the products will last only 11 years!

The extrapolated stress at 100 years is not very different to the 50 year value. In other words, the design factor for PVC pipes at a 100 years is only marginally lower than the design factor at 50 years.

If the time to failure for PVC pipes operating at the design hoop stress is determined using the regression analysis, a life of many millions of years is predicted. This is obviously ridiculous, but it serves to illustrate that adopting a 50 year design point does not mean that the life of plastics pipes are limited to 50 years.

A typical stress rupture curve for a PVC based material is shown in the figure below.