PVC Temperature Considerations

Maximum Service Temperature

PVC-U and PVC-M pressure pipes are suitable for use at service temperatures up to 50°C. For PVC-O pipes, the maximum continuous operating temperature should be limited to 45°C. Note that for all pipes conveying drinking water, compliance with the cold water requirements of AS/NZS 4020 is only valid up to 40°C and the Water Services Association of Australia (WSAA) recommend that water supply systems be limited to this value.

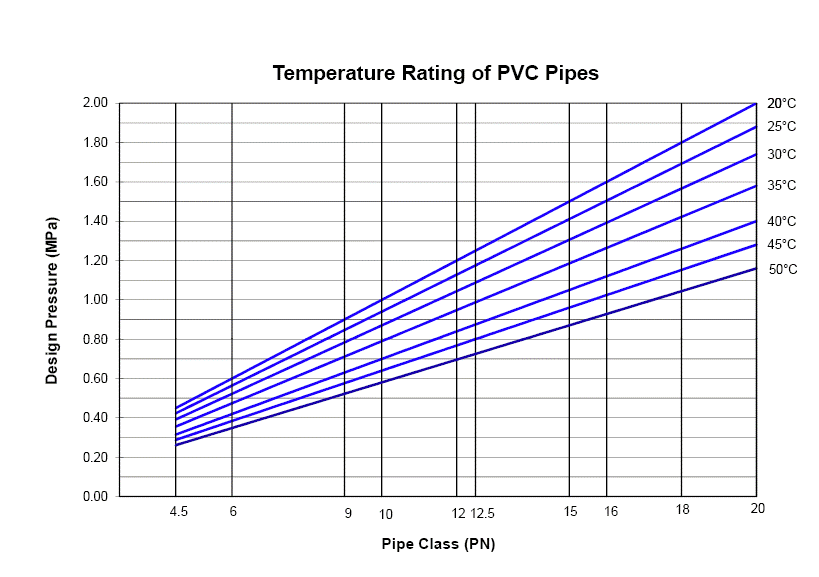

Effect of Temperature on Pressure Rating

Mechanical properties of PVC are temperature dependent. Nominal working pressures are determined at 20°C. For lower operating temperatures, the 20°C ratings are used, even though properties such as tensile strength are greater. As the temperature decreases, it is advisable to take additional care to avoid impact damage as the impact strength decreases with temperature. Sub-zero operating temperatures are specialist applications (see PVC pipes in low temperature applications) and reference can be made to Vinidex.

For temperatures greater than 20°C, the maximum working pressures of PVC pipes should be reduced. The following table gives the recommended maximum operating pressures for PVC-U, PVC-M and PVC-O pipes.

Maximum allowable operating pressures (MPa) for pipe pressure classes (PN)

| Pipe Material Temperature | PN 4.5 |

PN 6 |

PN 8 |

PN 9 |

PN 10 |

PN 12 |

PN 12.5 |

PN 15 |

PN 16 |

PN 18 |

PN 20 |

| 30°C | 0.39 | 0.52 | 0.70 | 0.78 | 0.87 | 1.04 | 1.09 | 1.31 | 1.39 | 1.57 | 1.74 |

| 35°C | 0.36 | 0.47 | 0.63 | 0.71 | 0.79 | 0.95 | 0.99 | 1.19 | 1.26 | 1.42 | 1.58 |

| 40°C | 0.32 | 0.42 | 0.56 | 0.63 | 0.70 | 0.84 | 0.88 | 1.05 | 1.12 | 1.26 | 1.40 |

| 45°C | 0.29 | 0.38 | 0.51 | 0.58 | 0.64 | 0.77 | 0.80 | 0.96 | 1.02 | 1.15 | 1.28 |

| 50°C | 0.26 | 0.35 | 0.46 | 0.52 | 0.58 | 0.70 | 0.73 | 0.87 | 0.93 | 1.04 | 1.16 |

The material temperature under consideration is the average temperature of the pipe wall under operational conditions.

In most instances it may be assumed that the pipe temperature is equal to the elevated temperature of the fluid being carried.

Where a temperature differential exists between the fluid in the pipe and the external environment, the operating temperature may be taken as the mean of the internal and external pipe surface temperatures.

For the usual case of turbulent flow of fluid inside the pipe, the inside surface temperature may be taken as the temperature of the fluid. The rate of heat transfer across the wall of a PVC pipe is low and provided the exterior of the pipe is well ventilated, the external surface will be near ambient.

Where heat transfer to or from the surrounding material is very slow, the external surface temperature will be near to that of the internal surface.

It may be necessary in critical cases to establish surface temperature characteristics by experiment. For the situation of a buried pipeline with flowing water, an appropriate ‘rule of thumb’ is:

Tm = (2Tw + Ts)/3

Tm = mean material temperature

Tw = water temperature

Ts = soil temperature

It should be noted that the pressure condition where flow is stopped should also be checked. In this event, water temperature and outside temperature will equalise

Temperature can also be averaged with respect to time.

The average temperature may be considered to be the weighted average of temperatures in accordance with the percentage of time spent at each temperature under operational pressures:

tm = t1 L1 + t2 L2 + … + tn Ln

where Ln = proportion of life spent at temperature tn

This approximation is reasonable provided the temperature variations from the mean do not exceed ± l0°C which is generally the case for pipes buried below 300 mm.

For most underground water supply systems, the overall mean temperature from meteorological records is appropriate for class selection purposes, since this represents the mean of the annual and diurnal sinusoidal temperature patterns.

For systems subjected to larger variations, the temperature for rating purposes should be taken as the maximum less 10°C. However, the peak temperature should not exceed 60°C.

Example:

A reticulation system is to be installed in a town with a mean ground temperature at pipe depth of 20°C. The December-February average is 25°C. Although diurnal variations occur with air temperatures up to 40°C during heatwave periods, water temperatures and ground temperatures at pipe depth do not exceed the mean of 27°C. A 50-year life is required at the standard factor of safety.

Weighted average temperature:

tm = 25(3/12) + 20.5(6/12) + 15(3/12)

= 6.25 + 10.25 + 3.75 = 20.25°C

Therefore, use rating for 20°C. This is the same result as taking the mean.

For a more sophisticated approach, refer to ISO 13760: Plastics pipes for conveyance of fluids under pressure – Miner’s rule – Calculation method for cumulative damage.

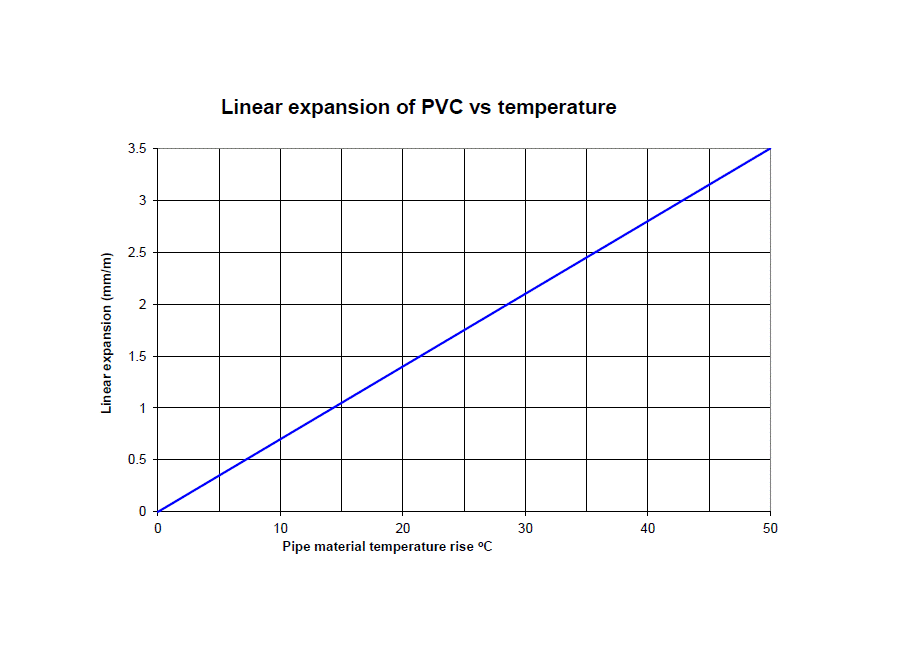

Expansion and Contraction

All materials expand and contract with changes in temperature and PVC has a relatively high rate of change.

The coefficient of thermal expansion is 7 x 10-5/°C.

A handy rule is 7 mm change in length for every 10 metres for every 10°C change in temperature.

Example:

A 150 metre line of PVC pipe is being installed with the temperature at 28°C. The service temperature will be 18°C. What allowance must be made for expansion?

- Find difference between maximum and minimum temperature, i.e. 28°C – 18° C = 10°C.

- Check chart above for expansion per metre.

10° C = 0.7 mm. - Multiply answer by total length of line

7 x 150 = 105 mm

This means the pipe will contract approximately 0.1 metres when in service. Methods of providing for thermal expansion or contraction will depend on the nature of the installation and whether it is above or below ground.