Performance of Moulded PVC Pressure Tees (VX-TN-5D)

Introduction

An innovative design of 100 mm tee 1 incorporates “reinforcing” ribs on the outside, running diagonally around the fitting. The purpose of this note is to explain how the bands work to improve the performance of the fitting, and the appropriate design procedures to capitalise on the advantage.

How it works

Although the term reinforcing rib is used, the term is a misnomer, since they do not act in the same way as steel or glass reinforcing, nor do the ribs provide simple stiffening as on the profiled wall sewer pipes now common in the marketplace.

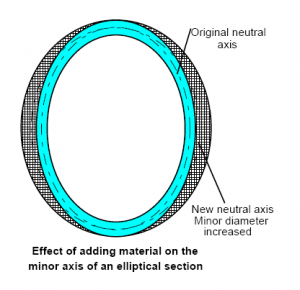

The action of the bands may be visualised by considering a plane at 45° through the “crutch” of the tee (along the line of the band). Without the rib, the cross-section has an elliptical shape, and when subjected to internal pressure, it attempts to become round, developing large bending stresses in the wall on the primary axes. The most damaging stresses are the tensile stresses on the inside at the crutch, which combine with the hoop tensile stresses to produce a total stress some 4 times that occurring in a pipe of the same wall thickness at the same pressure.

The ribs are not placed at this point however, but at the sides, with maximum thickness at the centre. Their effect is to move the neutral axis of the section outwards at the sides, resulting effectively in a more circular cross-section, and thus reducing the rounding bending moments.

Performance enhancement

Under static pressure the high bending stresses result in local yielding at the crutch of the tee, resulting in self-stress relief. The fittings thus exceed their required pressure ratings. At lower pressure levels, stress relief cannot occur, and under the influence of cyclic pressures, the peak stresses may exceed fatigue limits and result in premature failure.

Thus the major gain in performance derived from the new design is in the fatigue life, or number of cycles to failure. Under test, the tees have shown a very useful improvement, five times the life of plain tees (Test report, CSIRO, available).

Design recommendation

Vinidex’s Water Supply Manual for PVC pipe gives design guidelines for fatigue for pipes and fittings. For tees it is suggested that a factor of 4 be applied to the dynamic cycle amplitude before entering the design chart to determine the life of the fitting. For the new tee, for simplicity, it is proposed that the same factor be applied, but the resulting life be multiplied by five. Please note that at the time of printing only the 100 mm tee has been replaced by the new design.

It is important to note that the tees should not be regarded as a panacea for fatigue problems in pressure systems. Where high frequency cyclic pressures exist, all components of the system are subject to fatigue, and the first approach must be to reduce to amplitude and frequency of pressure cycling.