Installation of conduits in multi-duct banks (VX-TN-12G)

Introduction

It has been common practice for many years with PVC and PE Telecommunications and Electrical conduits to install multiple duct banks in a single trench. This note provides guidance on preferred installation practice.

Flexible pipes

PVC and PE conduits are flexible. This property enables them to accommodate strains from soil movements, expansion and contraction, seismic and other loadings that would rupture rigid pipes. All flexible pipes, regardless of material, require adequate support from the surround material to control vertical deformation due to soil loading. Proper support is obtained by the use good surround material and compaction practice.

For single pipes or conduits, the relationships between surround material properties, compaction levels, and pipe stiffness are well established and design procedures are covered by Australian Standard AS/NZS 2566.11. General guidance for the installation of PVC and PE pipes are given in AS/NZS 20322 and AS/NZS 20333 respectively.

Multi-duct banks

The requirements for support are no different for multiple ducts, but the practicalities of achieving it are somewhat more tricky. Clearly, ducts cannot be installed in contact with each other with any expectation of support all round. Conduits installed in this way will distort, possibly quite severely. If this type of installation is necessary, part compensation is possible using a stiffer pipe. A preferred method is to use sub-duct inside a larger duct.

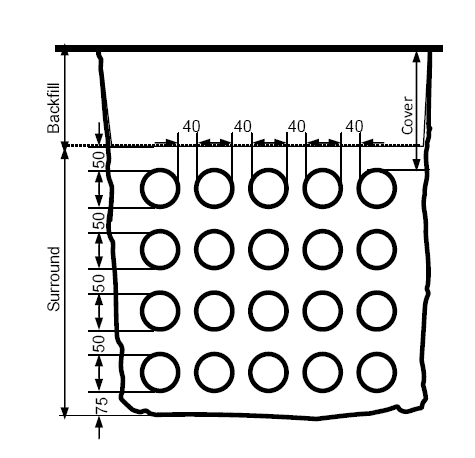

There must be sufficient space between the ducts to allow placement of surround material and its compaction. The requirement will vary somewhat with particular circumstances and size of pipe, but 40 mm could be considered a minimum convenient gap for a 100 – 150 mm duct to allow access with a hand compacting tool.

The height between each layer must be sufficient to enable a uniform bed to be achieved. 50 mm would be normally required. Spacers should be used to control depth of sand, removed before compaction and placement of the next layer.

The other obvious difficulty with multiple ducts is maintaining alignment during the compacting process. This requires somewhat more care than for single duct installations. Whilst alignment may not be functionally critical, displacement in one direction will detract from the ability to compact on the other side. Compaction should be carried out layer by layer, and spacer jigs used to maintain alignment.

The material used for surround of multiple ducts must be readily compatible and free flowing. Single sized crushed gravel offers the best support, but infiltration over time of soil from above may have longer term undesirable consequences. Low fines sand is the most commonly chosen material. Again, lower quality surround material may be used with increased spacing and higher stiffness ducts, but this play off is unlikely to offer a more economical solution.

Minimum cover over the top ducts should be in accordance with AS/NZS 2032 and AS/NZS 2033 recommendations, repeated here for reference:

| Not subject to vehicle loading | 300 mm |

| Subject to vehicle loading, not in roadways | 450 mm |

| In sealed roadways | 600 mm |

| In unsealed roadways | 750 mm |

| In embankment conditions | 750 mm |

| Subject to construction equipment loadings | 750 mm |

If these minimum cover heights cannot be met, additional protection of some form should be provided, eg., concrete slab or concrete encasement.

It is noteworthy that complete concrete encasement is quite common in critical locations, and this technique allows a lower stiffness pipe and closer spacing, within the constraints of the concrete depth and flowability. Note that deep pours can generate enough pressure and heat to collapse a PVC duct. Guidance is given for maximum concrete pour depth for classes of pipes in our Technical Note VX-TN-4F.

Minimum spacing for conduits in multi-duct banks – 100-150 mm conduit

References

- Standards Australia AS/NZS 2566.1 “Buried Flexible Pipelines Part 1: Structural Design” and Supplement 1: Commentary

- Standards Australia AS/NZS 2032 “Installation of PVC pipe systems”

- Standards Australia AS/NZS 2033 “Installation of polyethyene pipe systems”

- Vinidex Pty. Limited, VX-TN-4F, PVC pipes under external pressure”